Streamline ASCE 7-22 VS30 Site Classification Using DoReMi® MASW Seismographs with SEISMOWIN

The latest ASCE 7-22 standard requires Vs30 shear wave velocity measurements as a key parameter for site classification and seismic design. This shift makes reliable, efficient, and accurate seismic characterization of soils more critical than ever for geotechnical engineers, structural designers, and regulatory compliance.

The DoReMi® Seismograph is the perfect solution. Its digital telemetry system with embedded electronics offers unmatched efficiency, scalability, and modularity. Each channel operates as an independent seismograph, enabling networks from 1 to 255 channels for projects of any scale. Lightweight, durable, and powered by a rechargeable battery with smart standby mode, DoReMi® ensures seamless field deployment and uninterrupted operation. With over 15 years of proven reliability and hundreds of global clients, it is a trusted standard in seismic surveys and geotechnical site investigations.

Paired with SEISMOWIN, a complete seismic data management and analysis suite, the DoReMi® becomes a turnkey solution for Vs30 determination. SEISMOWIN’s MASW (Multichannel Analysis of Surface Waves) and ReMi (Refraction Microtremor) modules provide advanced tools to analyze both active-source surface waves and ambient noise, ensuring flexibility in diverse field conditions. MASW delivers detailed S-wave velocity profiles comparable to borehole logs—without being affected by velocity reversals—while ReMi excels in noisy environments where passive surveys are preferable.

Together, DoReMi® + SEISMOWIN empower engineers to quickly and confidently obtain Vs30 values required under ASCE 7-22, streamlining the entire workflow from data acquisition to final reporting. In-house design, production, and support guarantee fast service, expert training, and customization to meet project-specific needs.

✅ Turnkey Package Includes:

- DoReMi® Seismograph with 12 or 24+ channels and 4.5 Hz geophones

- SEISMOWIN software with MASW & ReMi modules

- Complete field-ready system with battery, cabling, and accessories

- Training and technical support

With this integrated solution, compliance with ASCE 7-22 site classification requirements is no longer a challenge—it’s an opportunity to deliver faster, more reliable, and cost-effective results.

DoReMi Seismograph: The All-in-One Solution

Key Features of DoReMi Seismograph:

- Modular Design: Scalable to support 1 to 255 channels, allowing flexible configurations for diverse projects.

- Embedded Recording Electronics: Electronics are embedded in the cable, reducing electromagnetic interference.

- Lightweight & Portable: Easily transported with a cable wheeler, ensuring smooth deployment in remote sites.

- Integrated Battery System: Built-in rechargeable battery ensures continuous and independent operation.

- Noise Reduction: Digitalization near the geophone minimizes noise and prevents data loss or crosstalk.

- Flexible Sensor Integration: Supports 4.5 Hz geophones, downhole sensors (SS-BH-5C), and other seismic equipment.

- Free Analysis Software: Compatible with any processing software, simplifying data management and interpretation.

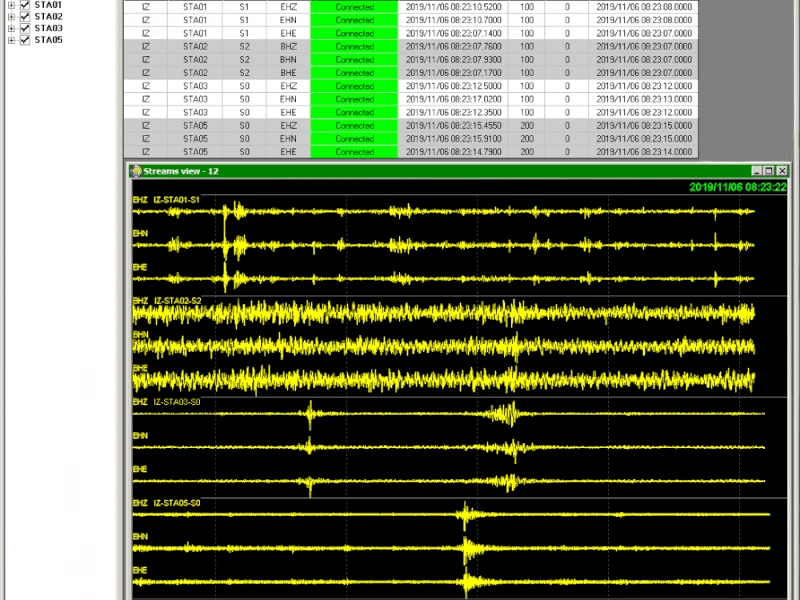

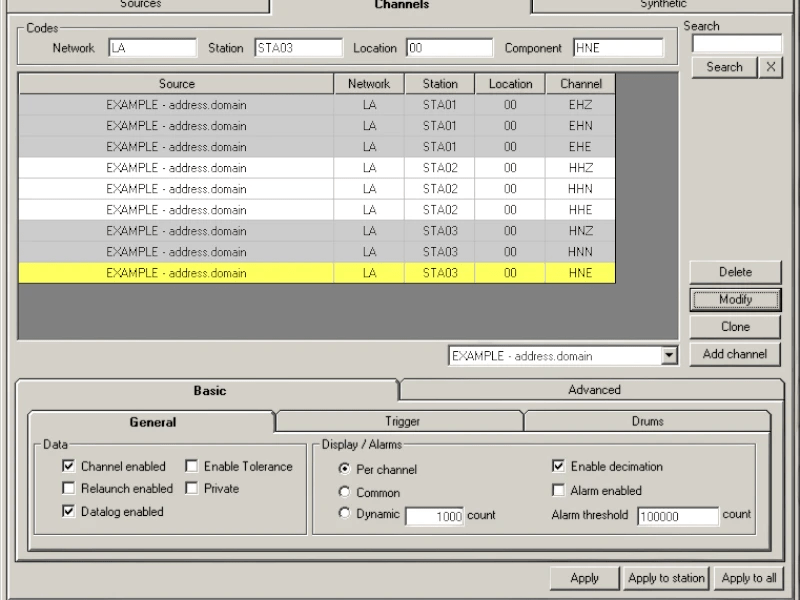

Advanced Software for Seamless Operation

The DoReMi Seismograph is complemented by advanced software tools, designed to streamline on-site data quality checks and post-processing workflows.

Key Software Capabilities:

- Pre-Shot Noise Monitoring: Ensures data integrity before acquisition.

- Downhole & Surface Data Management: Simplifies different acquisition scenarios.

- Signal Inversion & Overlapping: For SH shots and advanced processing.

- Data Filtering & Spectral Analysis: Advanced tools for FK and FV analysis.

- Roll-Along Acquisition: Simplifies large-area surveys.

- HVSR Preview: Horizontal-to-Vertical Spectral Ratio preview for subsurface mapping.

- Multi-Language Support: Available in English, Italian, and Chinese.

Applications of DoReMi Seismograph

- Seismic Hazard Assessment: Earthquake resilience site characterization.

- Geophysical Exploration: MASW, ReMi, Refraction, Reflection, and Downhole surveys.

- Infrastructure Projects: Foundation analysis and underground mapping.

- Resource Exploration: Aquifer detection, oil and gas reservoir profiling.

- Urban Development: Roadbed evaluations and soil stiffness assessments.

Data Outputs from DoReMi Seismograph

- 1D Shear Wave Velocity Profile:

- Vertical shear-wave velocity analysis for site characterization.

- 2D Shear Wave Velocity Profile:

- Comprehensive subsurface mapping when multiple acquisitions are performed.

These outputs are essential for geotechnical engineers, seismologists, and urban planners in making informed decisions.

Why Choose DoReMi Seismograph for MASW and ReMi Surveys?

- Dual Capability: Seamlessly supports both MASW and ReMi techniques.

- High Precision: Noise-free, reliable data acquisition.

- Scalable Design: Flexible configurations from 1 to 255 channels.

- Advanced Software Integration: Simplified analysis and data management.

- Portability: Lightweight design with modular architecture.

- Expert Support: Dedicated training, support, and consultation from QuakeLogic.

Conclusion

The DoReMi Seismograph by QuakeLogic represents a state-of-the-art solution for MASW and ReMi seismic surveys, offering unmatched flexibility, precision, and reliability. Whether it’s mapping shallow shear-wave velocity using MASW or profiling deeper subsurface layers with ReMi, DoReMi delivers results you can trust.

Experience precision, reliability, and innovation with the DoReMi Seismograph—your trusted partner in seismic exploration.

📞 For more information or to request a demo, contact us at:

Phone: +1-916-899-0391

Email: sales@quakelogic.net

Website: https://products.quakelogic.net/product/doremi-seismographs/