Silent Threats Demand Silent Detection

As unmanned aerial vehicles (UAVs) — or drones — become increasingly common in both civilian and military airspace, the need for reliable long-range UAV detection systems has never been greater. Conventional radar and optical systems face limitations in complex terrain or adverse weather. That’s where infrasound sensing technology comes in.

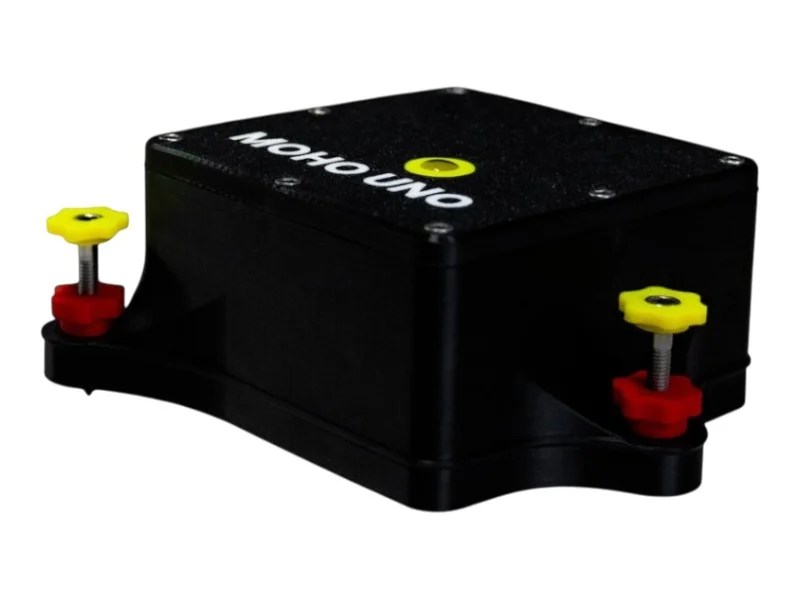

The SIS-1 Infrasound Sensor offers a cutting-edge approach to detecting and tracking UAVs using low-frequency acoustic waves, providing continuous, all-weather surveillance that complements existing radar or visual systems.

What Is Infrasound and Why It Works for UAV Detection

Infrasound refers to sound waves below the threshold of human hearing — typically below 20 Hz. These low-frequency waves can travel long distances and penetrate obstacles like hills, forests, and buildings.

Every UAV or drone produces a unique acoustic signature due to its propellers, engines, and aerodynamic behavior. The SIS-1 sensor detects these subtle infrasound emissions and distinguishes them from natural background noise through advanced filtering and signal processing.

This allows operators to identify, locate, and track drones even when they are invisible to the naked eye or radar — including small UAVs flying at low altitudes or beyond line of sight.

The SIS-1 Advantage

The SIS-1 Infrasound Sensor is purpose-built for field and defense applications requiring high sensitivity, low noise, and energy-efficient performance.

⚙️ Key Features

- Detection Range: 0.1 Hz – 50 Hz (−3 dB bandwidth)

- High Sensitivity: 2.5 – 3.5 mV/Pa for faint UAV signatures

- Ultra-Low Noise: Below the Low Noise Model (LNM) under 1 Hz

- Low Power Draw: < 5 mA @ 12 V — ideal for solar-powered systems

- Compact & Lightweight: 156 mm diameter, 67 mm height, 850 g

- Rugged Design: Operational between −20 °C and +60 °C

- Differential Output: For scalable multi-node detection networks

These specifications make SIS-1 perfect for deployment in permanent arrays, tactical mobile units, and long-term border installations.

Applications Across Defense and Security

QuakeLogic’s infrasound technology enables multiple use cases in national security and surveillance:

- UAV Detection & Tracking: Identify acoustic signatures of drones up to several kilometers away.

- Border Surveillance: Monitor unauthorized aerial movements in restricted zones.

- Explosion & Gunshot Detection: Detect and locate blasts or weapon discharges in real time.

- Multi-Hazard Monitoring: Integrate with environmental sensors for seismic, volcanic, and atmospheric observation.

- Smart Sensor Networks: Combine multiple SIS-1 units to form synchronized arrays for precise triangulation and trajectory calculation.

Easy Integration & Deployment

Each SIS-1 sensor is equipped with standard differential output and low-voltage operation, enabling direct integration with QuakeLogic dataloggers, signal processors, and visualization software. The system can be configured for:

- Real-Time UAV Acoustic Detection

- Automatic Threat Classification

- Event Recording and Remote Data Streaming

Combined with wind-noise reduction systems, SIS-1 delivers clear and reliable infrasound data even in challenging environments.

Why Choose QuakeLogic for UAV Detection

QuakeLogic brings decades of experience in seismic, infrasound, and structural monitoring systems to the defense and research sectors. The SIS-1 sensor reflects our commitment to precision engineering, reliability, and ease of deployment.

When integrated into your existing defense or border infrastructure, the SIS-1 becomes a force multiplier — adding a silent, passive detection layer capable of identifying aerial threats in all conditions.

Ready for Mission-Critical Monitoring

From UAV surveillance and perimeter protection to scientific field studies, SIS-1 is the trusted choice for organizations that demand uncompromised performance.

📩 Contact us today to learn how the SIS-1 Infrasound Sensor can strengthen your defense and UAV detection capabilities.