For decades, seismology has been defined by three translational components—X, Y, and Z.

Yet earthquakes do more than shift the ground; they also twist it. These subtle rotational motions hold vital insights into how seismic waves travel, how structures respond, and how hazards can be better understood. This is the foundation of rotational seismology, a rapidly advancing field that’s reshaping earthquake science.

Why Rotational Seismology Matters

Adding rotational motion to traditional measurements unlocks a fuller picture of seismic activity:

- Seismic wavefield analysis: enables accurate modeling of wave propagation, scattering, and shear wave splitting.

- Structural health monitoring: reveals torsional building responses often missed by translational sensors.

- Engineering applications: improves earthquake-resistant design and helps refine seismic codes.

By recording all six degrees of freedom (6-DOF), rotational seismology bridges the gap between theoretical models and real-world earthquake impacts.

Tellus-R: Precision in Rotational Sensing

At the forefront of this movement is Tellus-R, a low-noise rotational seismometer built for both research and applied monitoring. It combines unmatched sensitivity, low power consumption, and rugged reliability.

Key Performance Highlights:

- Resolution: 6×10⁻⁸ rad/s at 1 Hz

- Dynamic range: 117 dB

- Frequency range: 0.033–50 Hz (optional 0.01–100 Hz)

- Noise floor: –125 dB (rel. 1 rad/s² Hz)

- Power consumption: 30 mA at 10–18 VDC

- Calibration input: optional 1:1 verification channel

Tellus-R’s hard-coated anodized aluminum body (IP67/IP68) ensures protection against harsh environments. Compact (Ø180 mm × 140 mm, 2 kg) yet robust, it operates in any orientation across temperatures from –15 °C to +55 °C (–40 °C optional).

Applications Across Science and Engineering

- Earthquake research: capturing full 6-DOF motions near seismic sources

- Structural engineering: studying torsional dynamics in bridges, towers, and dams

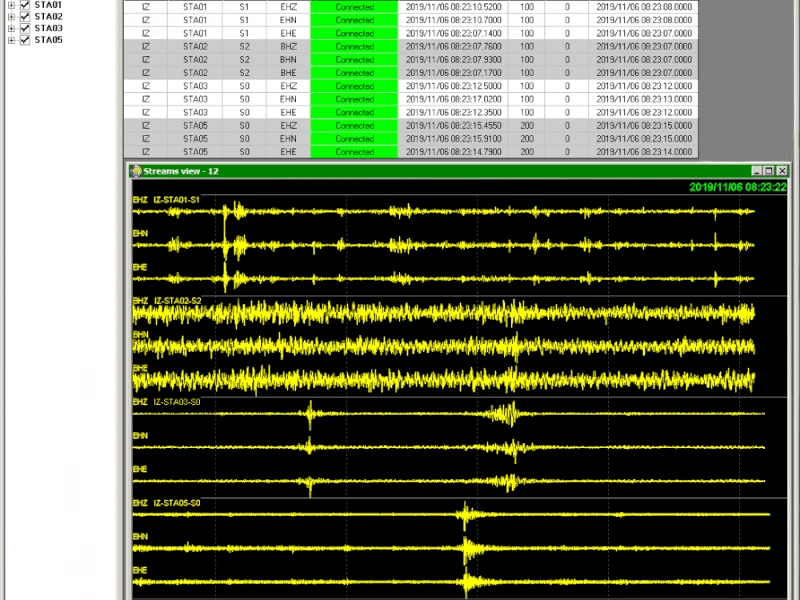

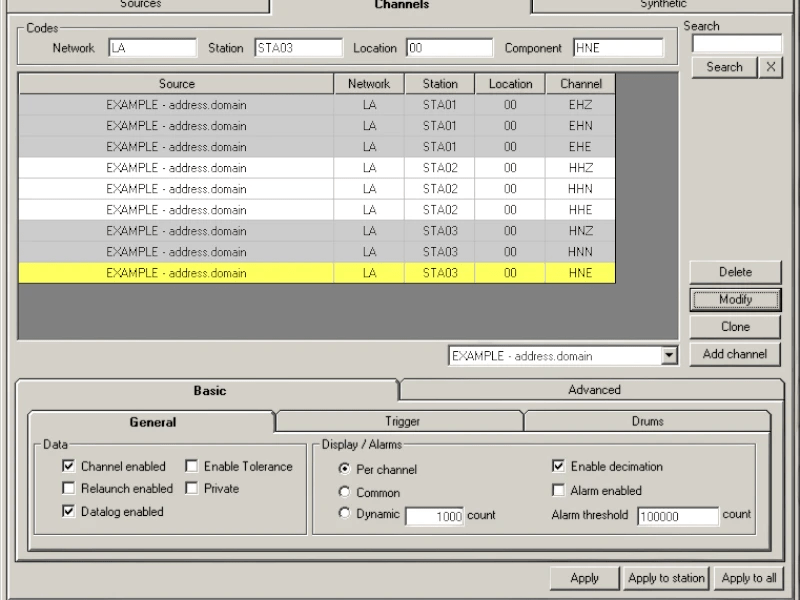

- Seismic arrays: enhancing data from permanent and temporary networks

- Geotechnical studies: advancing understanding of soil-structure interaction

Conclusion: Expanding the Future of Seismic Monitoring

Rotational seismology is redefining the way earthquakes are studied and structures are safeguarded. With its high precision, wide dynamic range, and field-proven durability, Tellus-R provides the critical measurements needed to push seismic science forward.

Seeing is Believing — explore how Tellus-R can revolutionize your seismic projects. Contact sales@quakelogic.net to learn more.