QuakeLogic proudly presents the ACEBOX accelerographs, the ultimate solution for comprehensive building seismic monitoring. Our high-fidelity accelerographs feature triaxial force balance accelerometers, an integrated datalogger, GPS, and Ethernet capabilities.

These sophisticated instruments are strategically placed at the roof, mid-level, and ground level of buildings to ensure accurate and reliable seismic data collection, as shown in the schematic below.

The ACEBOX is a compact all-in-one high-resolution accelerograph based on the reliable and field-proven SL06 recorder. It embeds three force balance accelerometers of the SA10 series, allowing for efficient and fast deployment. Within seconds of activation, the system is operational. Encased in robust, corrosion-resistant aluminum, the ACEBOX can be deployed in the field indefinitely with minimal environmental protection. Its weight and durability guarantee excellent ground coupling, and flexible data connectivity allows direct linkage to your central observatory. The ultra-fast SeedLink server accelerates data streaming up to 10 packets per second, making the ACEBOX the best option for Earthquake Early Warning Systems (EEWS).

Key features of the SARA ACEBOX include:

- Ultra-low noise design with an embedded FBA sensor featuring ultra-low noise and cross-axis sensitivity

- GPS synchronization with options for PPS or NTP when GPS is unavailable

- Wide power supply voltage range and internal NiMh battery for safe shutdown on power failure

- Edge computing capabilities, including alerting algorithms like P-wave analysis

- Ultra-fast SeedLink streaming protocol or custom protocols with substreaming capability

- Networking options including TCP, SSH, FTP, HTTP, ModBus, MQTT, Telnet, Telegram, and SMS

- VPN readiness for operation behind firewalls and NAT filters

- High-capacity local data storage and real-time measurements according to the UNI9916 norm

- Automatic frequency peak-picking with frequency shifting alarm reports

- Easy web browser configuration and management

- IP68 protection grade for harsh environments

Applications for the ACEBOX include EEWS, aftershock studies, reservoir microseismic monitoring, operational modal analysis (OMA), and structural health monitoring (SHM).

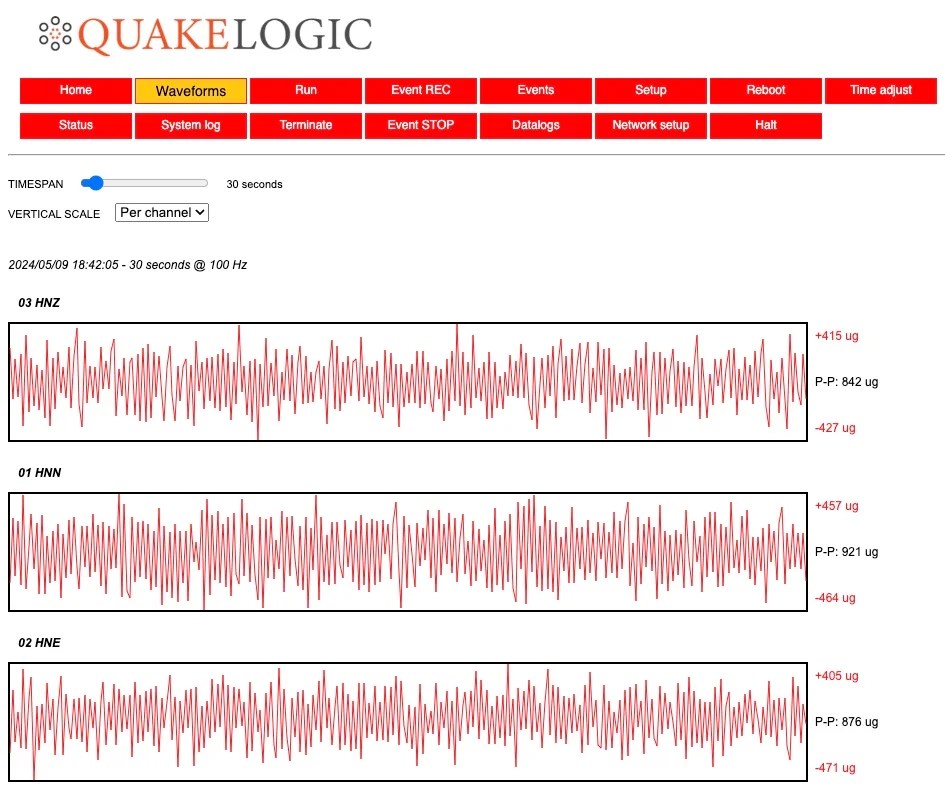

The GUI of ACEBOX is extremely easy to use and navigate.

Our accelerographs are designed to meet and exceed industry code regulations and standards, ensuring the highest level of safety and performance. The ACEBOX provides precise data essential for structural health monitoring and safety assessments, making it an invaluable tool for engineers and building managers.

For more information and sales inquiries, please contact us at sales@quakelogic.net or visit our product website at SARA ACEBOX Accelerographs.

About QuakeLogic

QuakeLogic is a leading provider of advanced seismic monitoring solutions, offering a range of products and services designed to enhance the accuracy and efficiency of seismic data acquisition and analysis. Our innovative technologies and expert support help organizations worldwide to better understand and mitigate the impacts of seismic events.

Contact Information

Email: sales@quakelogic.net

Phone: +1-916-899-0391

WhatsApp: +1-650-353-8627

Website: www.quakelogic.net

For more information about our products and services, please visit our website or contact our sales team. We are here to help you with all your seismic monitoring needs.

Thank you for choosing QuakeLogic. We look forward to assisting you with your seismic monitoring projects.